Scrambler and Cafe Racer styled production units of Tarform’s first model, Luna, were hand built in the Brooklyn Navy Yard and licensed by DOT for use on public roads. I led mechanical design and development of the drivetrain, battery pack, frame, suspension and bodywork - as well as personally assembling and wiring the first two prototypes. We worked with world class motocross engineers (Vitesse), LiPo battery innovators (Pymco), aluminum casting experts (TEI), and a renowned artisan metal former (Jay Donovan) to name a few of the talented team. Prototypes are shown above in bare aluminum, bronze and black finishes; photos by Founder Taras Kravtchouk and Ryan Handt.

Process - Design Development, Mechanical Engineering, Production Prototypes

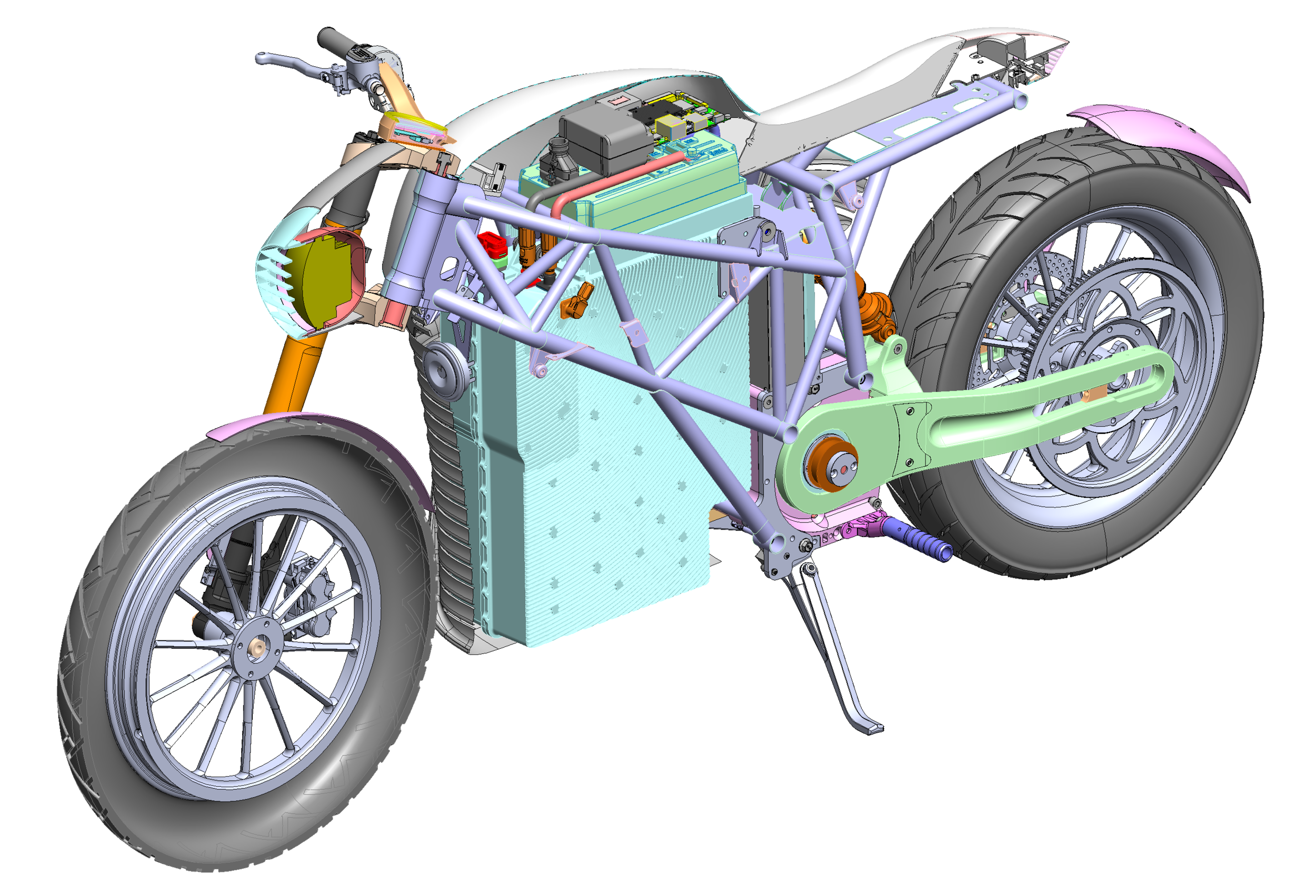

The core assembly and mechanical systems were designed in Solidworks CAD, including design for manufacture/assembly, the Gates belt drive, motor and powertrain, as well as the frame and structural assembly. When the pandemic forced most of our team to stay home in 2020, I had the time and opportunity to build the first bikes and prove their road-worthiness. Process photos above show the aluminum body and forming buck, frame fabrication and wire chasing.

Battery Development, Gen1 and Gen2 pack prototypes and assembly

Tarform’s engineering team worked with Pymco Power to develop a custom 650 amp, 10 kW battery pack to specification. We required the power supply to achieve 100 miles range and 100 miles per hour top speed, while maintaining thermal management and safety fail-safes. To achieve performance with minimal environmental impact, the stack-up was designed with Pymco’s patented assembly system - allowing the battery cells to be re-purposed at end-of-life.